Please contact us in time

infо@сitichl.соm +86-0379 64087499 Online MessageProduction capacity of shaft products:

Length 5000mm, rotary diameter 730mm mm, crankshaft machining of medium and high speed diesel engine

Length 5000mm, rotary diameter 1250mm mm, shaft parts processing

Length 2100mm, rotary diameter 200mm mm, camshaft and special-shaped rotating parts processing

Machining of concave camshaft with length 1500mm, rotary diameter 200mm

Length 1000mm, bore diameter 200mm, all kinds of medium and high speed diesel engine connecting rod processing

Main technical parameters:

Product Name |

Large Crankshaft |

Model |

According to customer requirement |

Material |

Cast iron or forged steel |

Stroke |

Standard |

Main Journal |

Standard |

Warranty |

12 months |

MOQ |

We accept small order, different products have different MOQ |

Supply Ability |

1000 pcs/month |

Delivery Time |

About 30 days after received payment |

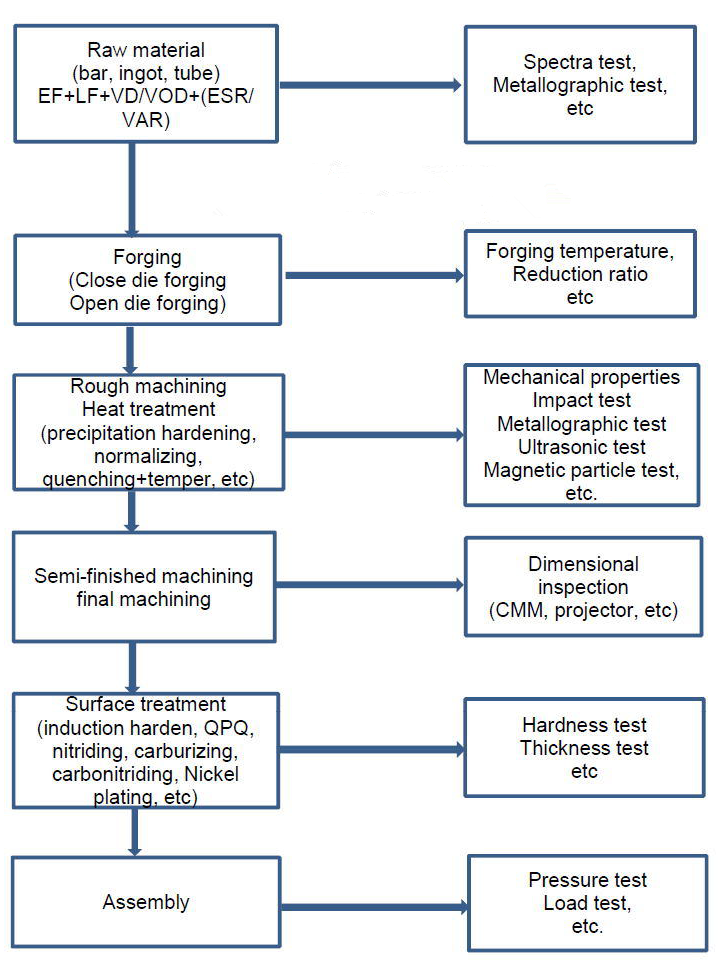

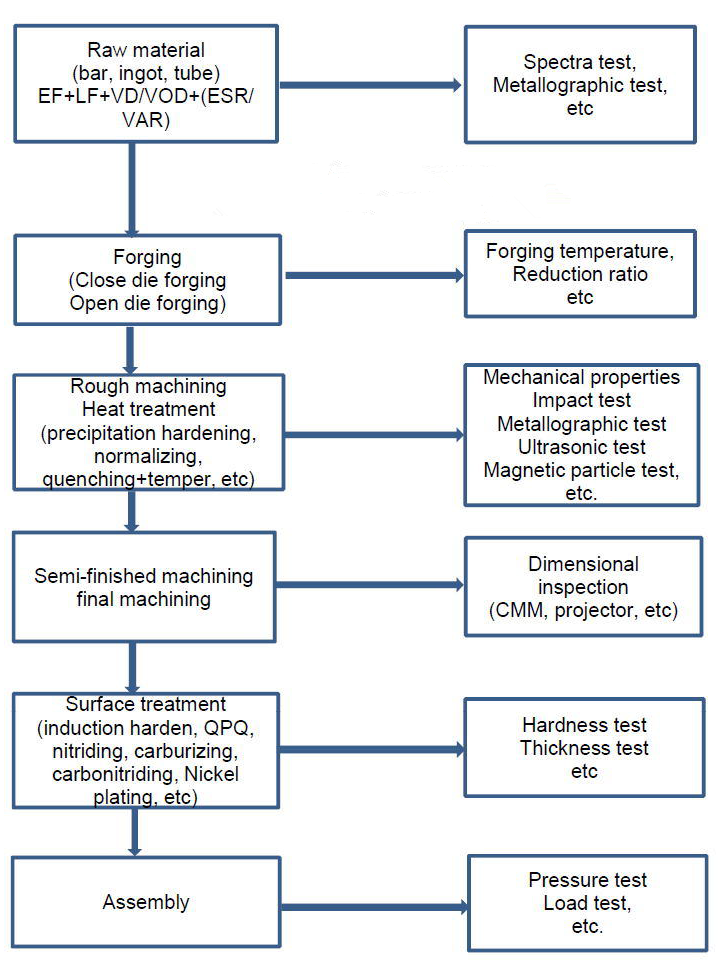

Quality Control

Our quality control begins from raw material, forging, heat treatment, semi-finished machining, final machining till assembly, each step is controlled strictly by our engineers, all of them have 10+ years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

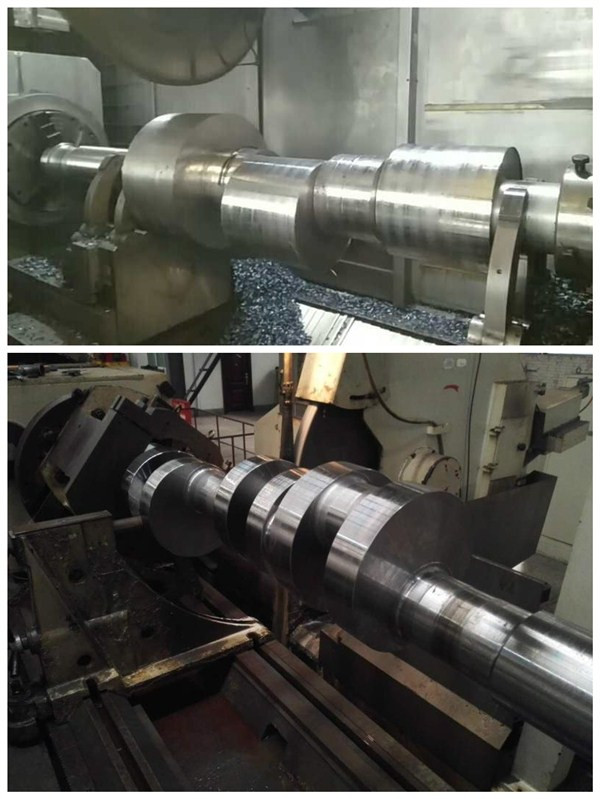

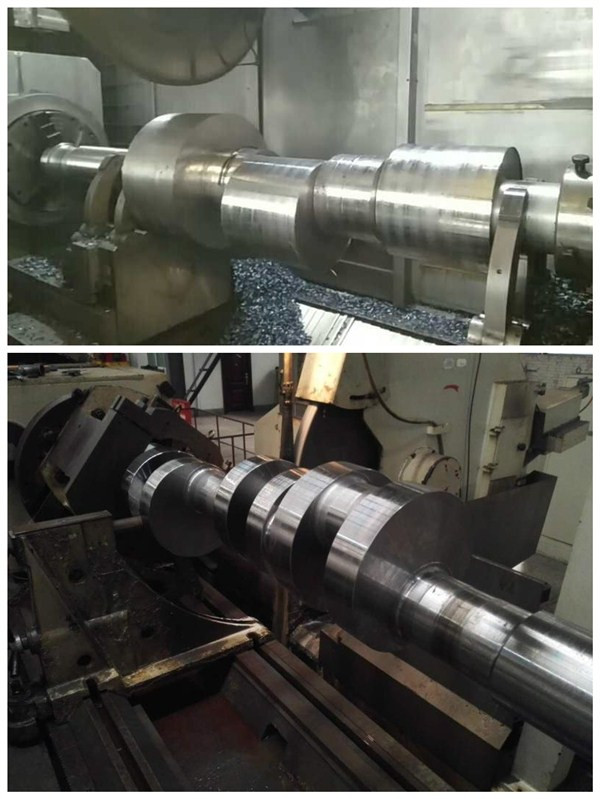

Crankshaft processing:

The crankshaft we made for American customer:

About us:

CITICTIC is national major industry and heavy machinery manufacturing base in the middle of china, we can supply the customers with important complete technical equipments in mining, non-ferrous metal, chemical industry, metallurgy, construction materials, environment protection, Large casting and forging parts for machines (girth gear, pinion shaft, roller, liner plate and so on) etc, power generating as well as other basic industries. The company can accept the packed engineering project. Our products are sold well to countries and regions in Asia, Africa, Europe, and Australia, and hold a large market share home and abroad.

We have a strong engineering team to ensure the quality stability for our customers' projects. All our engineers have more than 10 years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

For any forging product, only if you supply a sample or operating requirements, our engineers will design the optimal forging process and subsequent testing or manufacturing process for your product.

We have been achieving our mission and delivering the most cost-effective, highest quality solutions to our customers.

Production capacity of shaft products:

Length 5000mm, rotary diameter 730mm mm, crankshaft machining of medium and high speed diesel engine

Length 5000mm, rotary diameter 1250mm mm, shaft parts processing

Length 2100mm, rotary diameter 200mm mm, camshaft and special-shaped rotating parts processing

Machining of concave camshaft with length 1500mm, rotary diameter 200mm

Length 1000mm, bore diameter 200mm, all kinds of medium and high speed diesel engine connecting rod processing

Main technical parameters:

Product Name |

Large Crankshaft |

Model |

According to customer requirement |

Material |

Cast iron or forged steel |

Stroke |

Standard |

Main Journal |

Standard |

Warranty |

12 months |

MOQ |

We accept small order, different products have different MOQ |

Supply Ability |

1000 pcs/month |

Delivery Time |

About 30 days after received payment |

Quality Control

Our quality control begins from raw material, forging, heat treatment, semi-finished machining, final machining till assembly, each step is controlled strictly by our engineers, all of them have 10+ years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

Crankshaft processing:

The crankshaft we made for American customer:

About us:

CITICTIC is national major industry and heavy machinery manufacturing base in the middle of china, we can supply the customers with important complete technical equipments in mining, non-ferrous metal, chemical industry, metallurgy, construction materials, environment protection, Large casting and forging parts for machines (girth gear, pinion shaft, roller, liner plate and so on) etc, power generating as well as other basic industries. The company can accept the packed engineering project. Our products are sold well to countries and regions in Asia, Africa, Europe, and Australia, and hold a large market share home and abroad.

We have a strong engineering team to ensure the quality stability for our customers' projects. All our engineers have more than 10 years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

For any forging product, only if you supply a sample or operating requirements, our engineers will design the optimal forging process and subsequent testing or manufacturing process for your product.

We have been achieving our mission and delivering the most cost-effective, highest quality solutions to our customers.