Please contact us in time

сitiсic@outlook.com,citichm@outlook.com citichm@outlook.com +86-0379 64087499 Online MessageWith 30 -year rich industry experience and knowledge, we have earned specialization in manufacturing and supplying superior quality Large Gears. These are fabricated in conformity with defined industry standards, these compact and sturdy gears have standard working speed and torque measurement. The offered range is widely acknowledged by the customers for features like optimum performance, robust construction and longer life. These precision engineered gears are widely demanded across varied industries, where large gear reduction is required.

Advantages:

Products with Customers' Designs

Strong Machining & Heat Treatment Abilities

Strict Quality Control

Prompt Delivery

Experience in Cooperation with Fortune 500 Companies

Process:

Forging/Casting

Normalizing &Tempering-Proof Machinnig

Quenching &Tempering

Finish Machining(Teeth Grinding)

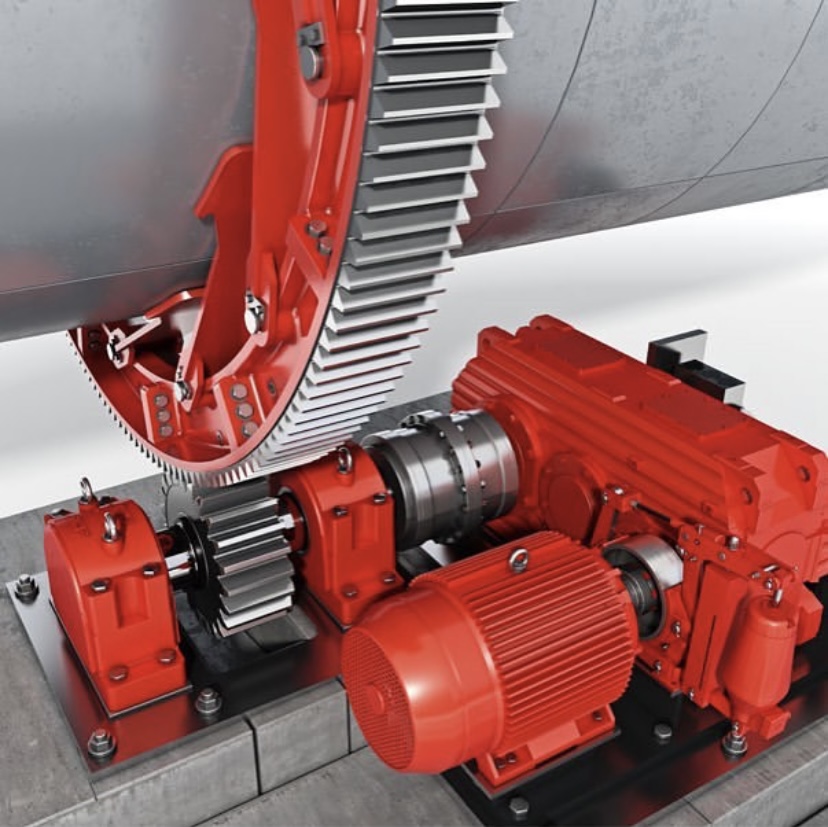

We can offer you in various process conditionsSolutions for Many End Markets and Applications

--Mining

--Metallurgy

--Power Generation

--Sugar

--Cement Plant

--Port Machinery

--Oil and natural

--Papermaking

--OEM gear case

--General Industrial

Specifications of Gear:

No. |

Item |

Description |

1 |

Diameter |

≤15m |

2 |

Module |

≤45 |

3 |

Material |

Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel |

4 |

Structure From |

Integrated, Half to Half, Four Pieces and More Pieces |

5 |

Heat Treatment |

Quenching & Tempering, Normalizing & Tempering, Carburizing & Quenching & Tempering |

6 |

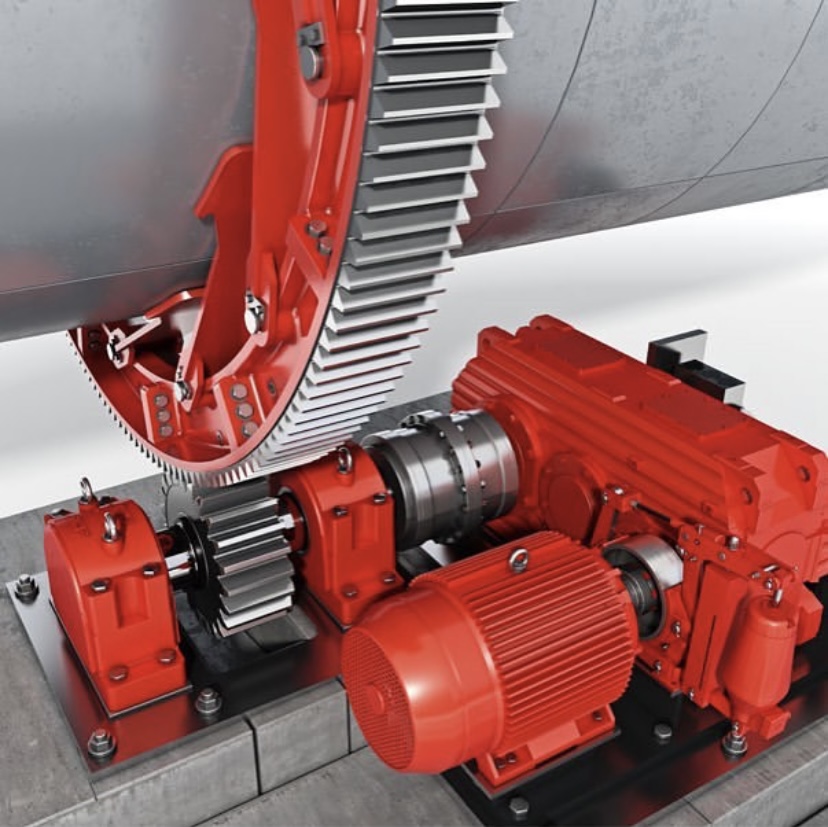

Tooth Form |

Annular Gear, Outer Gear Ring |

7 |

Standard |

ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

Testing Process:

· QA DOC: Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensio ns Check Report

· The data on chemical composition report and mechanical properties report are approved by third party, Luoyang

Ship Material Research Institute, CSIC.

· UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.

· Heat Treatment Report: provide original copy of heat treatment curve/time table.

The main products produced by our company:

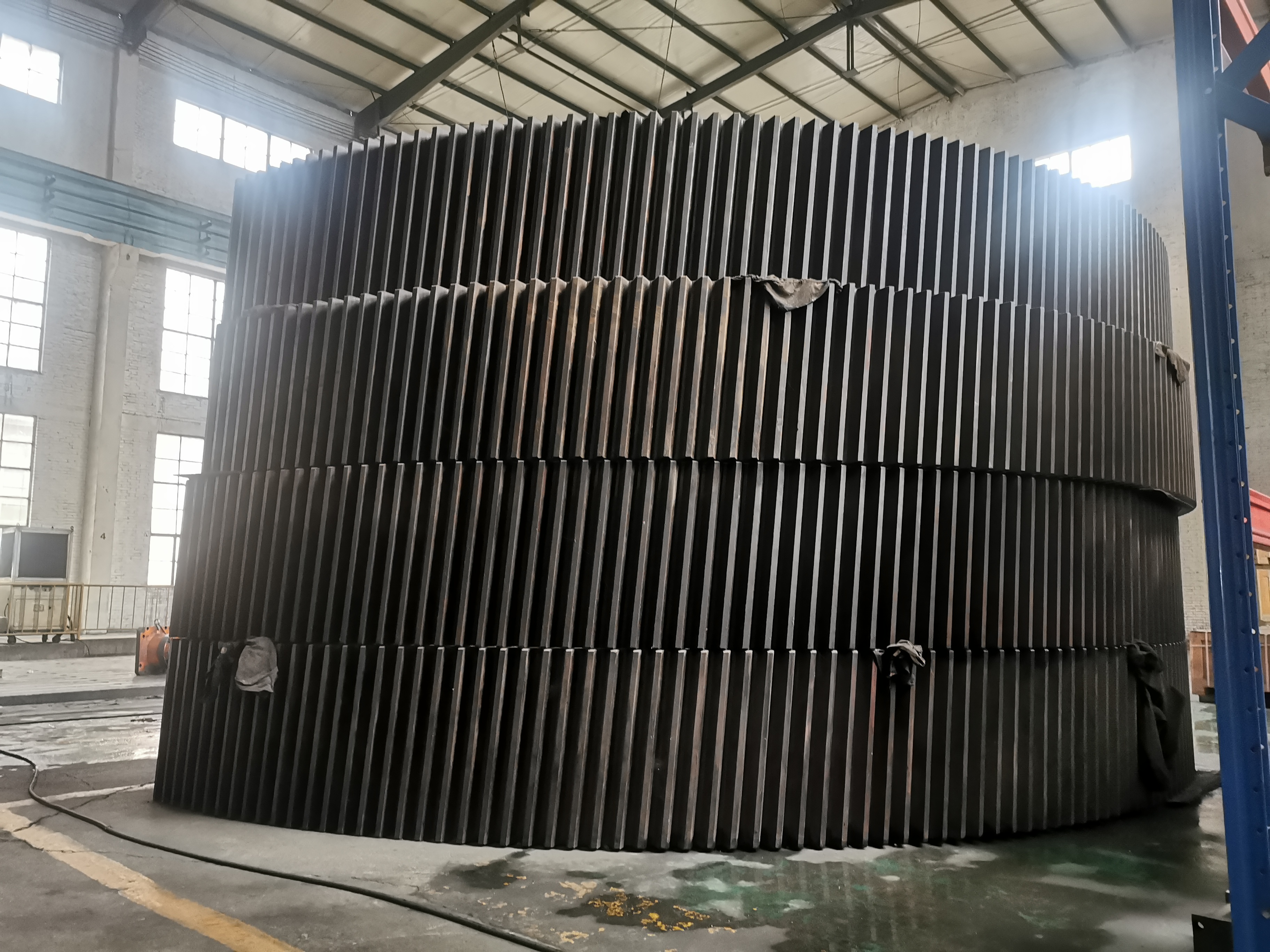

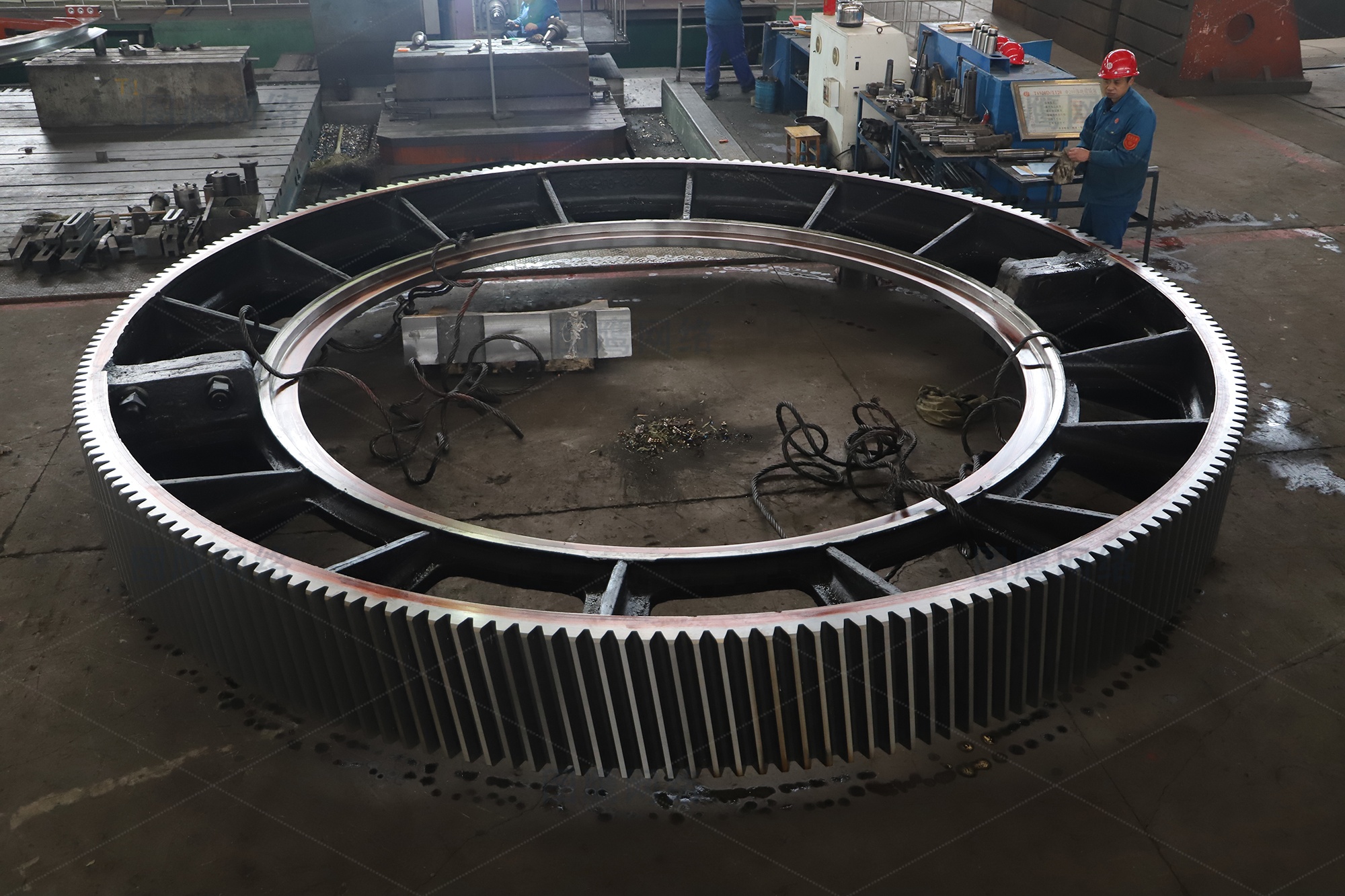

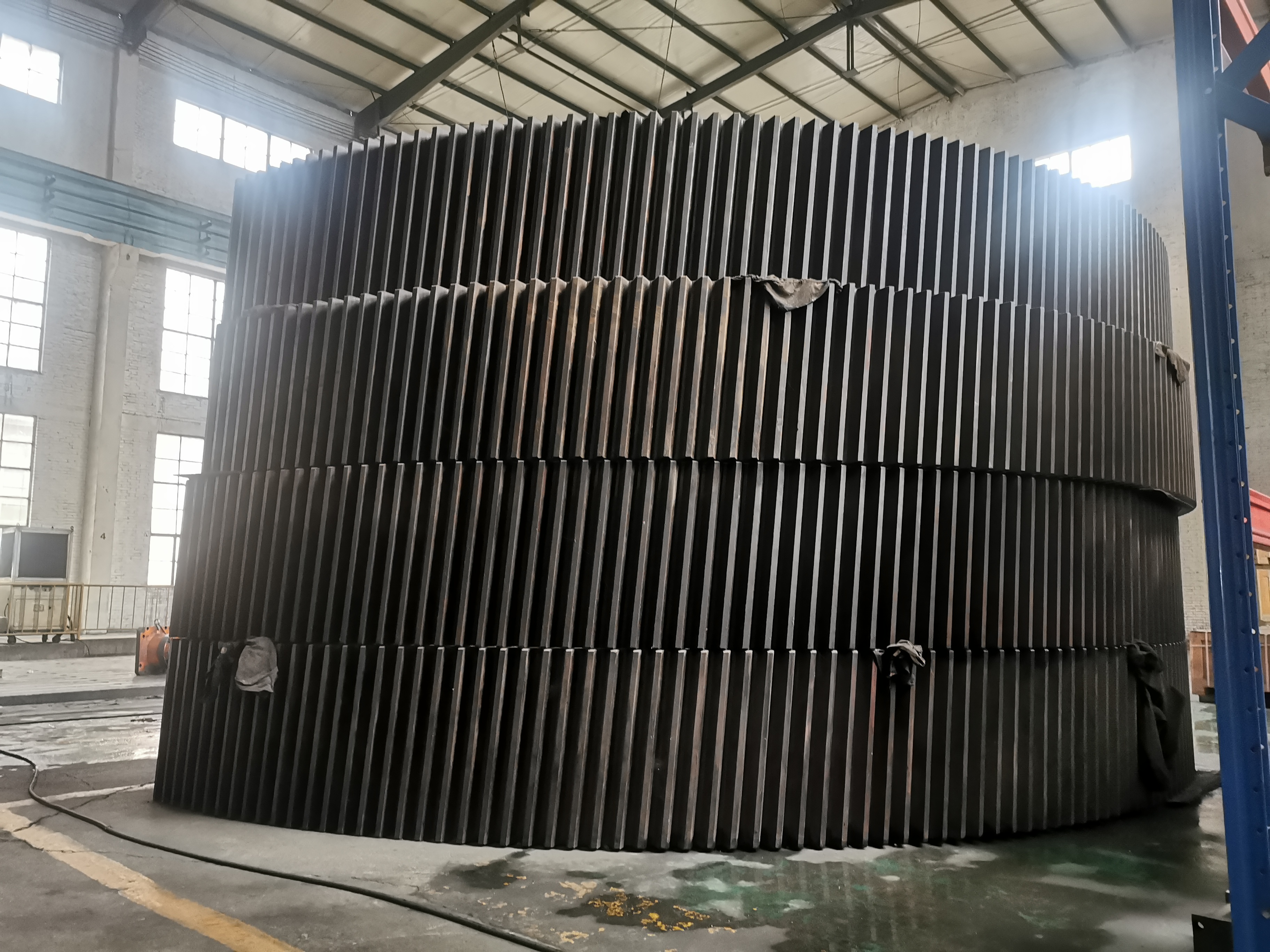

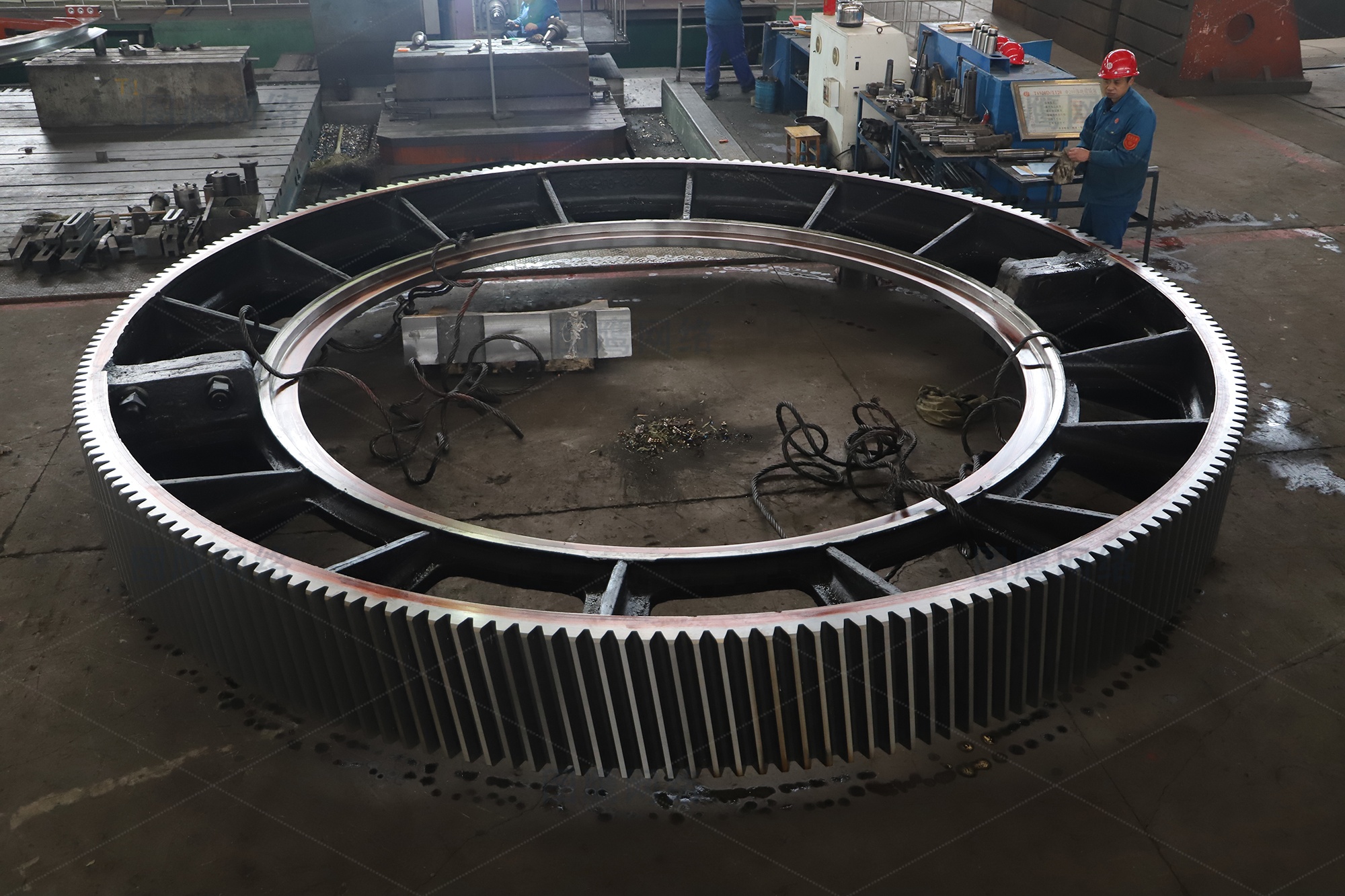

The photos for Large grith gear we made:

With 30 -year rich industry experience and knowledge, we have earned specialization in manufacturing and supplying superior quality Large Gears. These are fabricated in conformity with defined industry standards, these compact and sturdy gears have standard working speed and torque measurement. The offered range is widely acknowledged by the customers for features like optimum performance, robust construction and longer life. These precision engineered gears are widely demanded across varied industries, where large gear reduction is required.

Advantages:

Products with Customers' Designs

Strong Machining & Heat Treatment Abilities

Strict Quality Control

Prompt Delivery

Experience in Cooperation with Fortune 500 Companies

Process:

Forging/Casting

Normalizing &Tempering-Proof Machinnig

Quenching &Tempering

Finish Machining(Teeth Grinding)

We can offer you in various process conditionsSolutions for Many End Markets and Applications

--Mining

--Metallurgy

--Power Generation

--Sugar

--Cement Plant

--Port Machinery

--Oil and natural

--Papermaking

--OEM gear case

--General Industrial

Specifications of Gear:

No. |

Item |

Description |

1 |

Diameter |

≤15m |

2 |

Module |

≤45 |

3 |

Material |

Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel |

4 |

Structure From |

Integrated, Half to Half, Four Pieces and More Pieces |

5 |

Heat Treatment |

Quenching & Tempering, Normalizing & Tempering, Carburizing & Quenching & Tempering |

6 |

Tooth Form |

Annular Gear, Outer Gear Ring |

7 |

Standard |

ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

Testing Process:

· QA DOC: Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensio ns Check Report

· The data on chemical composition report and mechanical properties report are approved by third party, Luoyang

Ship Material Research Institute, CSIC.

· UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.

· Heat Treatment Report: provide original copy of heat treatment curve/time table.

The main products produced by our company:

The photos for Large grith gear we made: