Please contact us in time

сitiсic@outlook.com,citichm@outlook.com citichm@outlook.com +86-0379 64087499 Online MessageSingle Rope Mine Hoist

Application

This series of products are used in coal mines, metal mines and non-metal mine lifters, minerals, lifting personnel and decentralized materials or equipment, etc., and can also be used for other traction transportation.

Working principle

The motor passes the power to the coil of the winding wire rope through the reducer to achieve the lifting and lowering of the container; slow down by electric transmission; disc brakes are controlled by hydraulic and electrical controls; the depth indication of the container is realized through the position indication system; Through various sensors and control elements composed of machine, electricity, liquid joint control system to achieve the monitoring and protection of the entire machine; through computer and network technology, information transmission inside and outside the hoist is realized.

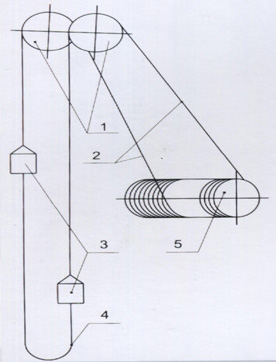

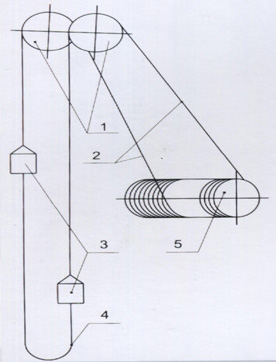

1. Sheave

2. Steel rope

3. Containers

4. Tail

5. Spindle device

Working principle of single rope mine hoist spindle device

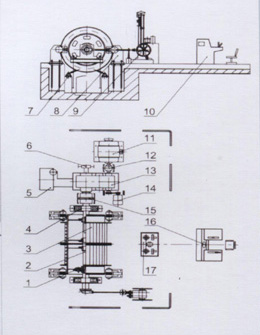

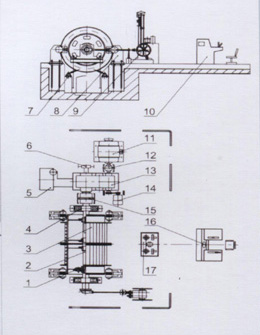

1. Rope adjusting device

2. Main shaft

3. Roll

4. Main bearing shaft

5. Lubrication station

6. Disk depth indicator transmission

7. Lock Brake

8. Disc Brake

9. Square depth indicator

10. Bevel console

11. Motor

12. Spring coupling

13. Reducer

14. Speed measuring generator unit

15. Gear coupling

16. Disk depth indicator

17. Hydraulic stations

Complete supply range

Main machine, sheave device, Different forms of consoles, depth indicator, hydraulic station, lubrication station; electric drag and control system, information transmission system; At request of users, Other specifications can be produced to meet the needs of users.

JK Series Single-rope Mine Hoist Technical Parameter Table

Model |

Drum |

Tension |

Tension |

Rope |

Lift height (m) |

Max |

Reduce |

Motor |

|||||

No. |

Dia |

Width |

1-layer |

2-layer |

3-layer |

||||||||

m |

KN |

mm |

m |

m/s |

r/min |

||||||||

JK-2×1.5 |

1 |

2.0 |

1.5 |

62 |

24 |

305 |

650 |

1025 |

5.2 |

20.0 |

1000 |

||

JK-2×1.5 |

31.5 |

||||||||||||

JK-2×1.8 |

1.80 |

375 |

797 |

1246 |

20.0 |

||||||||

JK-2×1.8 |

31.5 |

||||||||||||

JK-2.5×2 |

2.5 |

2.00 |

83 |

28 |

448 |

945 |

1475 |

5.0 |

20.0 |

750 |

|||

JK-2.5×2 |

31.5 |

||||||||||||

JK-2.5×2.3 |

2.30 |

525 |

1100 |

1712 |

20.0 |

||||||||

JK-2.5×2.3 |

31.5 |

||||||||||||

JK-3×2.2 |

3.0 |

2.20 |

135 |

36 |

458 |

966 |

1513 |

6.0 |

20.0 |

||||

2JK-2×1 |

2 |

2.0 |

1.00 |

62 |

40 |

24 |

182 |

406 |

652 |

7.0 |

11.2 |

||

2JK-2×1 |

20.0 |

||||||||||||

2JK-2×1 |

31.5 |

||||||||||||

2JK-2×1.25 |

1.25 |

242 |

528 |

838 |

11.2 |

||||||||

2JK-2×1.25 |

20.0 |

||||||||||||

2JK-2×1.25 |

31.5 |

||||||||||||

2JK-2.5×1.2 |

2.5 |

1.20 |

83 |

65 |

28 |

843 |

8.8 |

11.2 |

|||||

2JK-2.5×1.2 |

20.0 |

||||||||||||

2JK-2.5×1.2 |

31.5 |

||||||||||||

2JK-2.5×1.5 |

2.5 |

1.50 |

83 |

||||||||||

Single Rope Mine Hoist

Application

This series of products are used in coal mines, metal mines and non-metal mine lifters, minerals, lifting personnel and decentralized materials or equipment, etc., and can also be used for other traction transportation.

Working principle

The motor passes the power to the coil of the winding wire rope through the reducer to achieve the lifting and lowering of the container; slow down by electric transmission; disc brakes are controlled by hydraulic and electrical controls; the depth indication of the container is realized through the position indication system; Through various sensors and control elements composed of machine, electricity, liquid joint control system to achieve the monitoring and protection of the entire machine; through computer and network technology, information transmission inside and outside the hoist is realized.

1. Sheave

2. Steel rope

3. Containers

4. Tail

5. Spindle device

Working principle of single rope mine hoist spindle device

1. Rope adjusting device

2. Main shaft

3. Roll

4. Main bearing shaft

5. Lubrication station

6. Disk depth indicator transmission

7. Lock Brake

8. Disc Brake

9. Square depth indicator

10. Bevel console

11. Motor

12. Spring coupling

13. Reducer

14. Speed measuring generator unit

15. Gear coupling

16. Disk depth indicator

17. Hydraulic stations

Complete supply range

Main machine, sheave device, Different forms of consoles, depth indicator, hydraulic station, lubrication station; electric drag and control system, information transmission system; At request of users, Other specifications can be produced to meet the needs of users.

JK Series Single-rope Mine Hoist Technical Parameter Table

Model |

Drum |

Tension |

Tension |

Rope |

Lift height (m) |

Max |

Reduce |

Motor |

|||||

No. |

Dia |

Width |

1-layer |

2-layer |

3-layer |

||||||||

m |

KN |

mm |

m |

m/s |

r/min |

||||||||

JK-2×1.5 |

1 |

2.0 |

1.5 |

62 |

24 |

305 |

650 |

1025 |

5.2 |

20.0 |

1000 |

||

JK-2×1.5 |

31.5 |

||||||||||||

JK-2×1.8 |

1.80 |

375 |

797 |

1246 |

20.0 |

||||||||

JK-2×1.8 |

31.5 |

||||||||||||

JK-2.5×2 |

2.5 |

2.00 |

83 |

28 |

448 |

945 |

1475 |

5.0 |

20.0 |

750 |

|||

JK-2.5×2 |

31.5 |

||||||||||||

JK-2.5×2.3 |

2.30 |

525 |

1100 |

1712 |

20.0 |

||||||||

JK-2.5×2.3 |

31.5 |

||||||||||||

JK-3×2.2 |

3.0 |

2.20 |

135 |

36 |

458 |

966 |

1513 |

6.0 |

20.0 |

||||

2JK-2×1 |

2 |

2.0 |

1.00 |

62 |

40 |

24 |

182 |

406 |

652 |

7.0 |

11.2 |

||

2JK-2×1 |

20.0 |

||||||||||||

2JK-2×1 |

31.5 |

||||||||||||

2JK-2×1.25 |

1.25 |

242 |

528 |

838 |

11.2 |

||||||||

2JK-2×1.25 |

20.0 |

||||||||||||

2JK-2×1.25 |

31.5 |

||||||||||||

2JK-2.5×1.2 |

2.5 |

1.20 |

83 |

65 |

28 |

843 |

8.8 |

11.2 |

|||||

2JK-2.5×1.2 |

20.0 |

||||||||||||

2JK-2.5×1.2 |

31.5 |

||||||||||||

2JK-2.5×1.5 |

2.5 |

1.50 |

83 |

||||||||||