Please contact us in time

сitiсic@outlook.com citichm@outlook.com +86-0379 64087499 Online Message

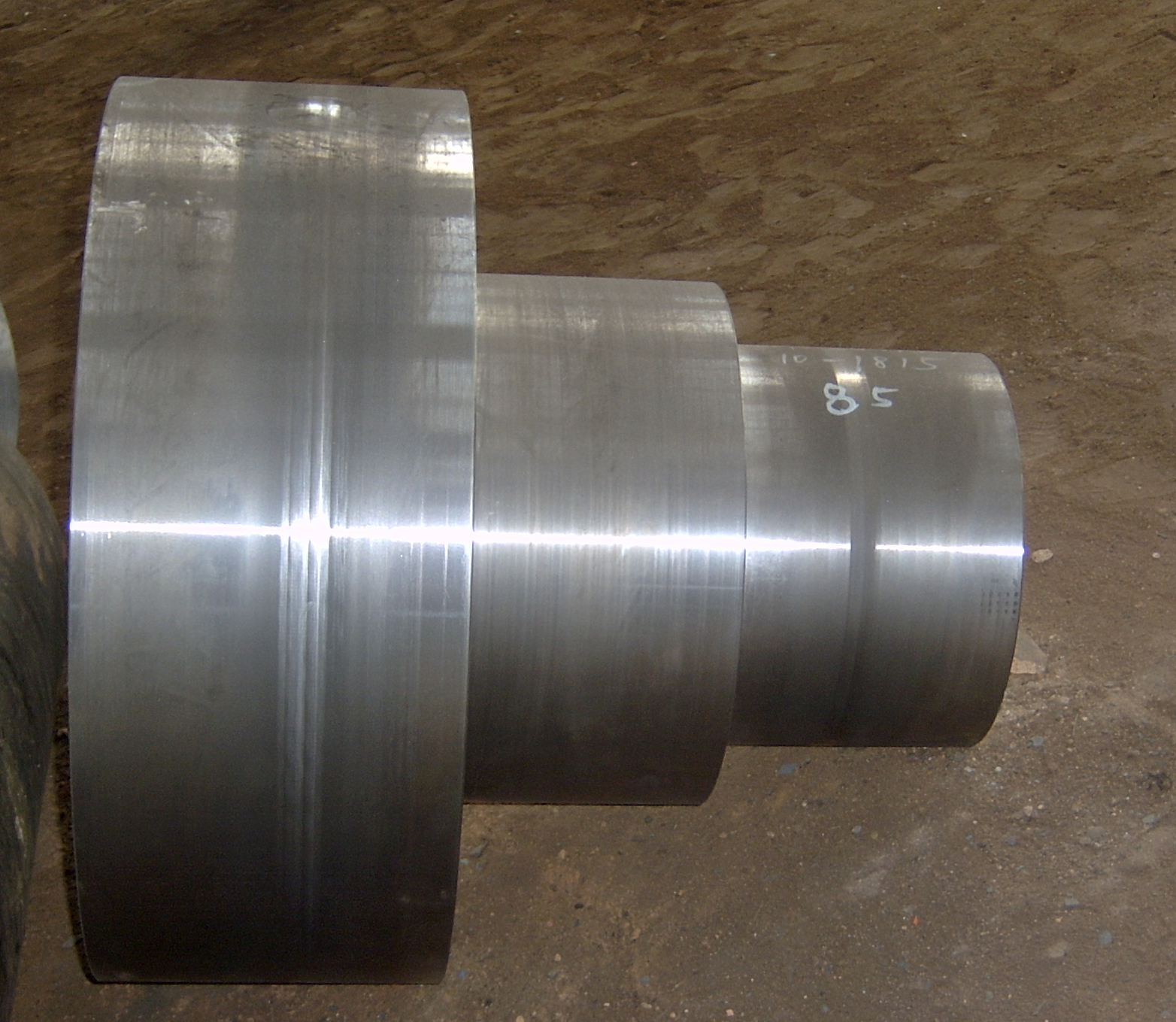

We offer the rotary kiln support roller

Rotary Kiln Support Rollers are backed by latest technology and provide desired support to cables and other related products. These support rollers are driven to rotate using friction between roller surface and web. The small friction torque of the roller bearings also allow higher speed operations and helps in avoiding possibilities of slippage due to presence of large air film between roller surface and web.

We bring forth to our customers Kiln Support Roller for a Rotary Kiln that are designed by our experienced processionals, who hold vast knowledge in this domain. Our professionals uses refractory material that are lined to protect the steel shell and reduce radiation losses.

Rotary Kiln Support Roller Advantages

Weight: from 3 tons to 90 tons per piece

Application: The products can be widely used in the area of cement mill, rotary kiln etc.

Certificate: ISO9001:2000 etc.

Material: Carbon alloy, low alloy steel ZG20SiMn,ZG35SiMn, ZG35CrMo etc

Process: molding-pouring-cooling-shaking out-heat treatment

Machine: rough machined, semi-finished machined, finished machined

Heat treatment: Normalized, Normalized and Tempered, Quench and Tempered.

Rotary Kiln Support Roller Features

Coming with small friction torque of roller bearings

Rollers are close together that decrease pulling tension

Manufactured as per defined industry standards

Can also be custom designed as per client's specific requirements

Durable finish and reliable performance

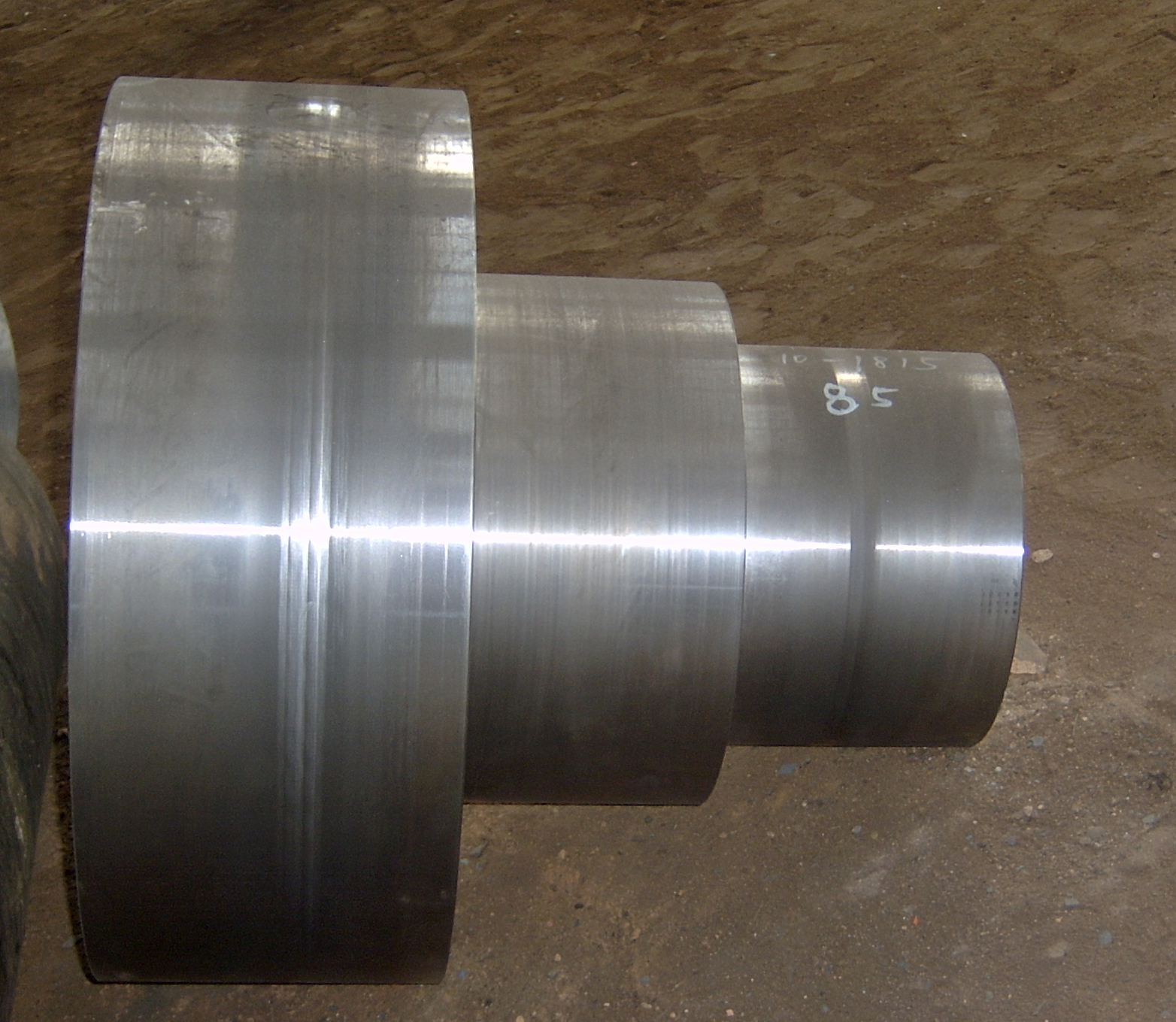

We offer the rotary kiln support roller

Rotary Kiln Support Rollers are backed by latest technology and provide desired support to cables and other related products. These support rollers are driven to rotate using friction between roller surface and web. The small friction torque of the roller bearings also allow higher speed operations and helps in avoiding possibilities of slippage due to presence of large air film between roller surface and web.

We bring forth to our customers Kiln Support Roller for a Rotary Kiln that are designed by our experienced processionals, who hold vast knowledge in this domain. Our professionals uses refractory material that are lined to protect the steel shell and reduce radiation losses.

Rotary Kiln Support Roller Advantages

Weight: from 3 tons to 90 tons per piece

Application: The products can be widely used in the area of cement mill, rotary kiln etc.

Certificate: ISO9001:2000 etc.

Material: Carbon alloy, low alloy steel ZG20SiMn,ZG35SiMn, ZG35CrMo etc

Process: molding-pouring-cooling-shaking out-heat treatment

Machine: rough machined, semi-finished machined, finished machined

Heat treatment: Normalized, Normalized and Tempered, Quench and Tempered.

Rotary Kiln Support Roller Features

Coming with small friction torque of roller bearings

Rollers are close together that decrease pulling tension

Manufactured as per defined industry standards

Can also be custom designed as per client's specific requirements

Durable finish and reliable performance